THE BASROC SYSTEM

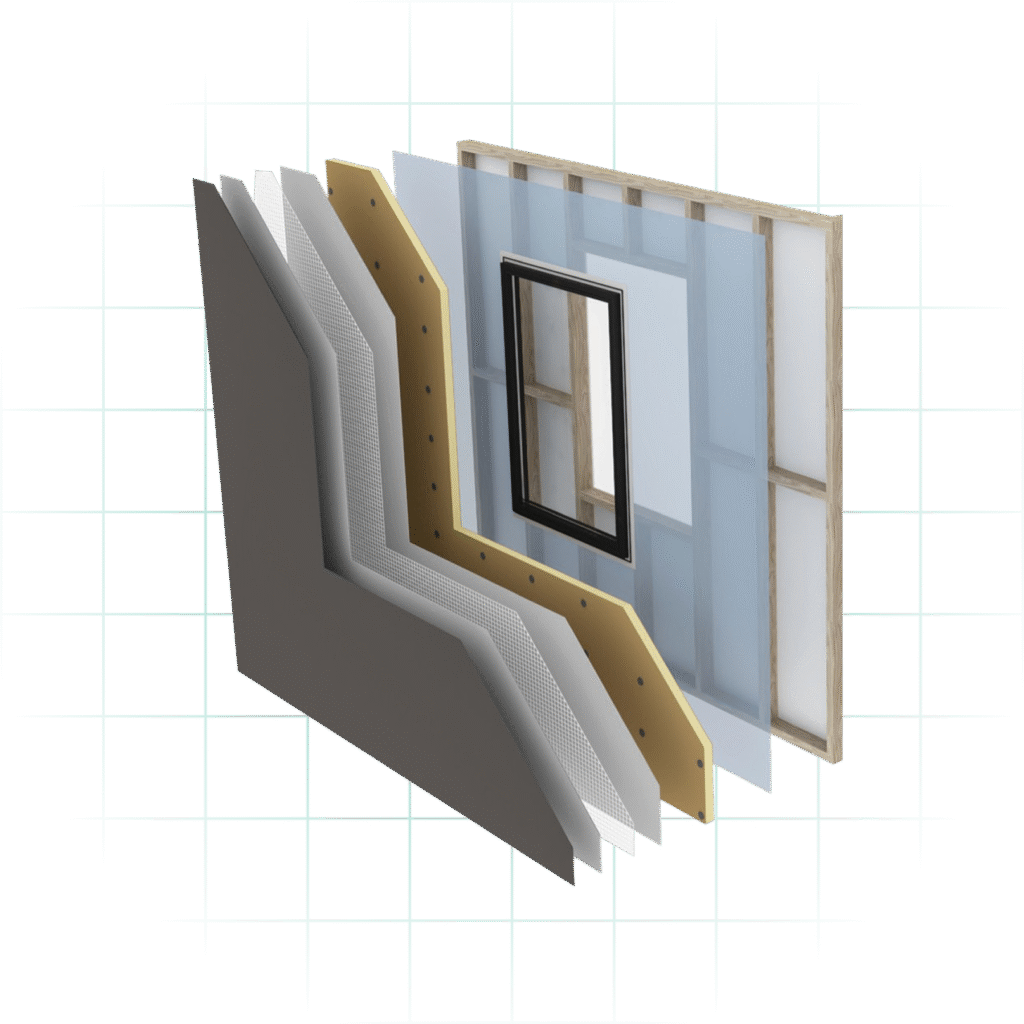

THE BASROC EXTERNAL WALL

CLADDING SYSTEM

THE BASROC EXTERNAL WALL CLADDING SYSTEM

THE BASROC SYSTEM

PATENTED DESIGN

100% SILICA FREE

FIRE RATED

LIGHTWEIGHT (10KG)

ACOUSTIC SHIELD

WATER REPELLENT

CODEMARK CERTIFIED

10 YEAR WARRANTY

HYDROPHOBIC

THE NEW GENERATION OF TECH BUILDING

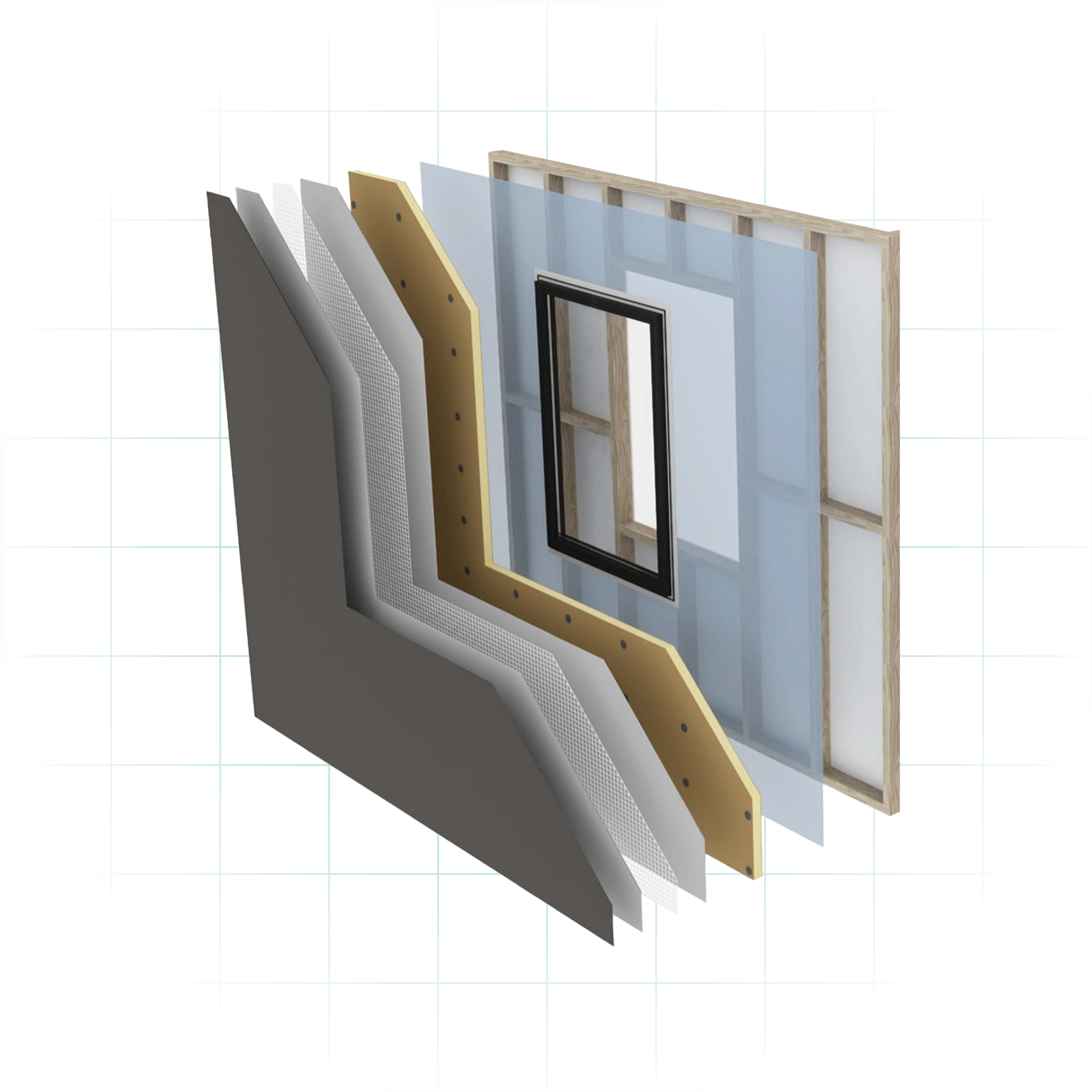

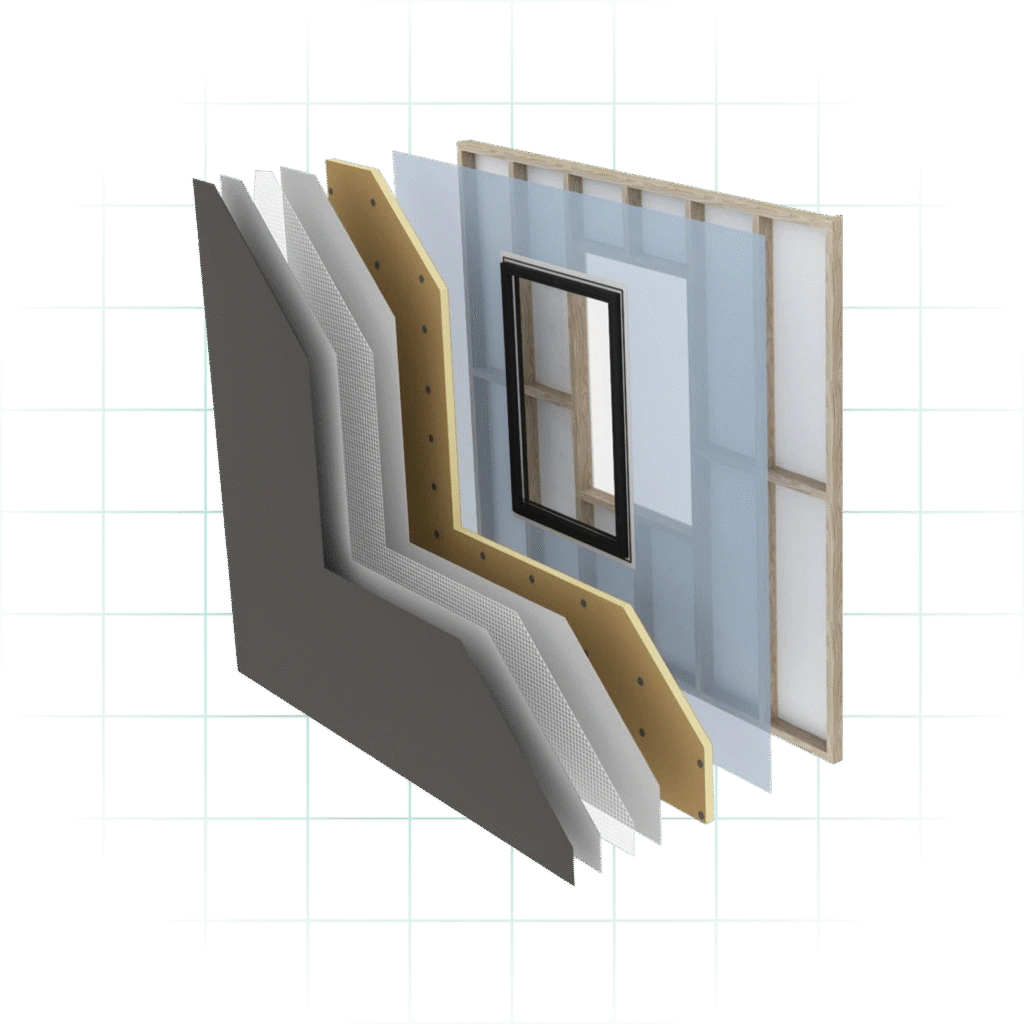

Basroc System Components

Patented Design

Breathable (Vapour Permeable) Reflective or Non-Reflective Builders Paper

Basroc Flashing Tape

Built for flexibility

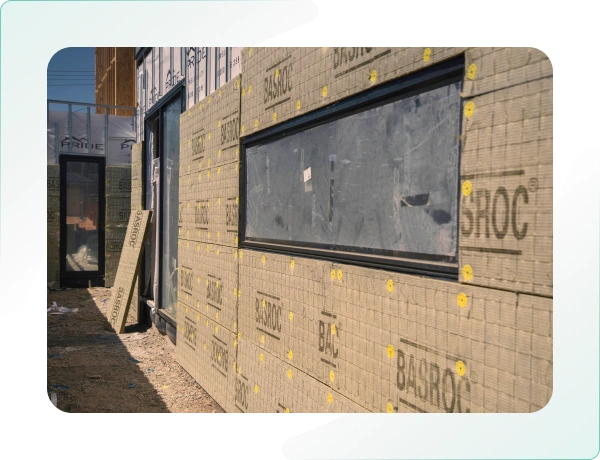

Our Basroc Panel Render and Texture systems have been thoroughly tested and proven to deliver reliable, high-quality performance on a wide range of projects.

The freedom to design without compromise. Basroc products offer versatile design options

while providing the durability and protection needed to meet demanding project requirements.

Our experienced team is available to provide on-site assistance, helping to ensure your installation goes smoothly and meets the highest standards.

We supply detailed manuals, specifications, and technical documents to support your team

throughout every stage of the project.

Stay ahead with our ongoing training programs, designed to equip your team with the latest skills and product knowledge for future projects.

EASY INSTALLATION

Our panels are lightweight and can be easily cut, making handling and installation quicker and more efficient on-site

Engineered with convenience in mind, the panels are light and manageable enough for a

single person to install without the need for extra help.

Whether you're a qualified tradesperson or an experienced DIY enthusiast, our panels are

simple to work with and designed for a smooth installation process.

Thanks to the precision design and quality manufacturing, our panels reduce the risk of

installation errors, saving you time, money, and potential warranty headaches.

THE BASROC SYSTEM

HIGH-PERFORMANCE, SUSTAINABLE CLADDING

SOLUTION FOR SERIOUS CONSTRUCTION

HIGH-PERFORMANCE, SUSTAINABLE

CLADDING SOLUTION FOR SERIOUS

CONSTRUCTION

Basroc is a patented, high-performance, silica-free cladding system engineered for Australia’s toughest conditions. Codemark Certified, fire-rated, and future-ready, it delivers safety, speed, and long-term protection.

Longer Building Lifespan

Basroc is fire resistant, water repellent, and vapour permeable, protecting structures from heat, moisture, and trapped internal damp. It reduces risk on site and over time, helping prevent water damage, mould, and structural failure.

Fire, water, and trapped moisture are three of the biggest threats to a building’s lifespan. For homeowners, Basroc means fewer repairs, lower maintenance costs, and safer living conditions. For businesses, it means reduced liability, long-term asset protection, and confidence that the building meets code, now and in the years ahead.

THE SMARTER, SAFER, SIMPLER CHOICE

The Basroc System

Traditional Systems

- 100% crystalline silica-free – safe for your team

- Often contain crystalline silica (OH&S risk)

- No cutting bay or power tools needed – faster workflows

- Require cutting bays, power tools, dust control

- FRL up to 90/90/90 (AS 1530.4:2014) – Protects lives, protects your build

- Limited or variable fire ratings

- BAL-FZ compliant (AS 3959:2018) – Helping with government jobs

- May not be approved for BAL-FZ zones

- Vapour permeable and hydrophobic – Fewer callbacks, lower warranty risk

- Vapour barriers often added separately

- Knife-cuttable on-site, no dust extraction required – Real cost reduction

- Extra PPE, masks, or compliance plans needed

- NCC 2022 compliant (Volumes One & Two) – Credibility to win repeat work

- Risk of falling short of current NCC standards

- CodeMark certified (CM70139) – strengthen your reputation in this competitive market

- Not all systems are fully certified

- Suitable for Class 1–10 buildings

- Require adaptation for certain build classes or unable to be used on certain build classes

- Full system, designed to work together

- Components often sourced from different suppliers

In Stock. On Site. On Time.

Don’t wait weeks for production or deal with long lead times Basroc is available off-the-shelf through select distributors, meaning it’s ready when you are. For high-volume projects, supply can also be scaled quickly to meet demand.

Basroc panels are typically delivered to site within 3 days to 1 week, depending on location and volume. Texture finishes are made to order and require an additional 7 days. This fast turnaround helps keep projects on track, with minimal waiting between order and install.

Your Trusted Supplier, Now with Basroc.

Now available off-the-shelf through Bowens locations, Basroc is easier to specify, easier to source, and backed by a supplier you already trust.

It’s one more reason Basroc feels like the safer, smarter choice. Bowens: Leaders in Timber, Hardware & Building Products

SAFE WORK AUSTRALIA

The Silica Ban is just the start – Is your system ready?

THE FUTURE OF CLADDING

What it means for cladding

compliance risk

Basroc removes the compliance risk – Cut silica exposure & install complexity

Basroc contains no crystalline silica. Not in the panel, render, or texture. Panels can be cut with a utility knife without dust or water. That means no compliance headaches, no future restrictions, and a safer, faster install from day one. When the rules tighten, you’ll already be ahead.

Specifiers are already requesting silica-free systems and Basroc answers that call without compromise on quality & durability

Basroc silica safety + lightweight

ENGINEERED FOR SAFETY

THE SCIENCE BEHIND SAFER CLADDING

Basroc Fire Resistance

Tested to AS 1530.4:2014 Basroc achieves a Fire Resistance Level (FRL) of up to 90/90/90 when installed on timber framing and -/90/90 on steel. This means it maintains structural adequacy, integrity, and insulation for 90 minutes in a certified fire test.

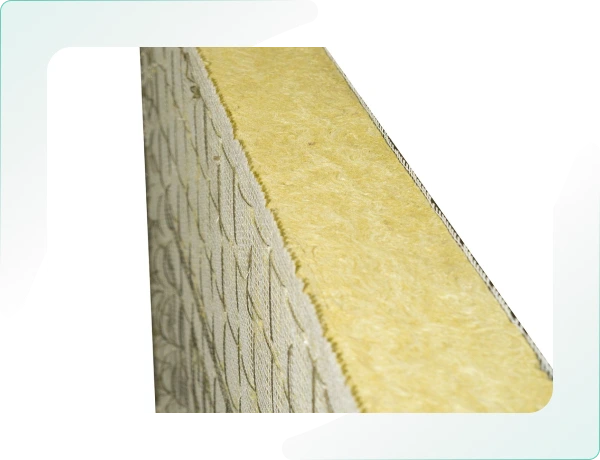

Non-combustible materials

The core of the system is made from high-density mineral wool, which does not burn, melt, or emit toxic smoke.

Basroc Water Repellence

Hydrophobic Panel Surface. The Basroc Panel is water repellent, meaning it resists moisture ingress while maintaining its structural integrity and insulation properties.

Surface coating

The full Basroc system includes a trowel-on acrylic texture finish, which provides additional water resistance and protects against weathering.

Breathable System

The mineral wool core and render system are vapour permeable, allowing trapped moisture inside the wall cavity to escape, reducing the risk of mould, rot, or material degradation.

Wrap + Panel Combo

Basroc is installed over a vapour-permeable wall wrap, creating a breathable envelope that balances moisture management with thermal control.

SMARTER, SAFER CLADDING

ENGINEERED FOR SAFETY

THE SCIENCE BEHIND SAFER CLADDING

Basroc Fire Resistance

Tested to AS 1530.4:2014 Basroc achieves a Fire Resistance Level (FRL) of up to 90/90/90 when installed on timber framing and -/90/90 on steel. This means it maintains structural adequacy, integrity, and insulation for 90 minutes in a certified fire test.

Non-combustible materials

The core of the system is made from high-density mineral wool, which does not burn, melt, or emit toxic smoke.

Basroc Water Repellence

Hydrophobic Panel Surface. The Basroc Panel is water repellent, meaning it resists moisture ingress while maintaining its structural integrity and insulation properties.

Surface coating

The full Basroc system includes a trowel-on acrylic texture finish, which provides additional water resistance and protects against weathering.

Breathable System

The mineral wool core and render system are vapour permeable, allowing trapped moisture inside the wall cavity to escape, reducing the risk of mould, rot, or material degradation.

Wrap + Panel Combo

Basroc is installed over a vapour-permeable wall wrap, creating a breathable envelope that balances moisture management with thermal control.

SMARTER, SAFER CLADDING

Basroc Energy Efficiency

NO SILICA, NO CUTTING BAY, NO FUSS

BASROC IS DESIGNED FOR FASTER, SAFER INSTALLS

No crystalline silica

Basroc is completely silica-free, removing one of the most serious health hazards in the construction industry. There’s no risk of silica dust inhalation during cutting or handling, which means no need for respirators, extraction systems, or designated cutting bays.

No cutting bay required

Panels can be cut with a standard utility or serrated knife—no power tools needed. This dramatically reduces dust, noise, and OH&S risks on site.

No wet trades or water handling

Unlike some systems, Basroc doesn’t require water on-site for cutting or cleanup, or a specific saw & vacuum combination. This reduces slip risks and makes setup and pack-down faster.

Lightweight, One-Person Handling

Panels are light enough for one person to lift, carry, and install. This enables smaller crew sizes, lowers fatigue risk, and improves efficiency on tight-access or upper-level jobs.

Panel size: 2200mm x 600mm

The dimensions are manageable for a single installer without machinery or lifting assistance in most scenarios.

Basroc Panel is available in thicknesses of 50mm, 75mm & 100mm (special order) so there's bound to be a Basroc option to fit your project.

Direct fix or cavity options

Basroc is suitable for both direct fix and cavity wall applications, making it adaptable across project types.

Simple fixing system

Installed using standard screws and washers—no specialist tools or hidden fasteners. Screws are concealed under render, simplifying finish work.

Clear, step-by-step manuals

Installation is fully documented, including layouts for control joints, penetration detailing, and substrate requirements. This removes guesswork and reduces reliance on on-site trial and error.

Compatible with timber or steel frames

Works with standard framing systems (AS 1684.2 for timber, NASH for steel), with no modification required.